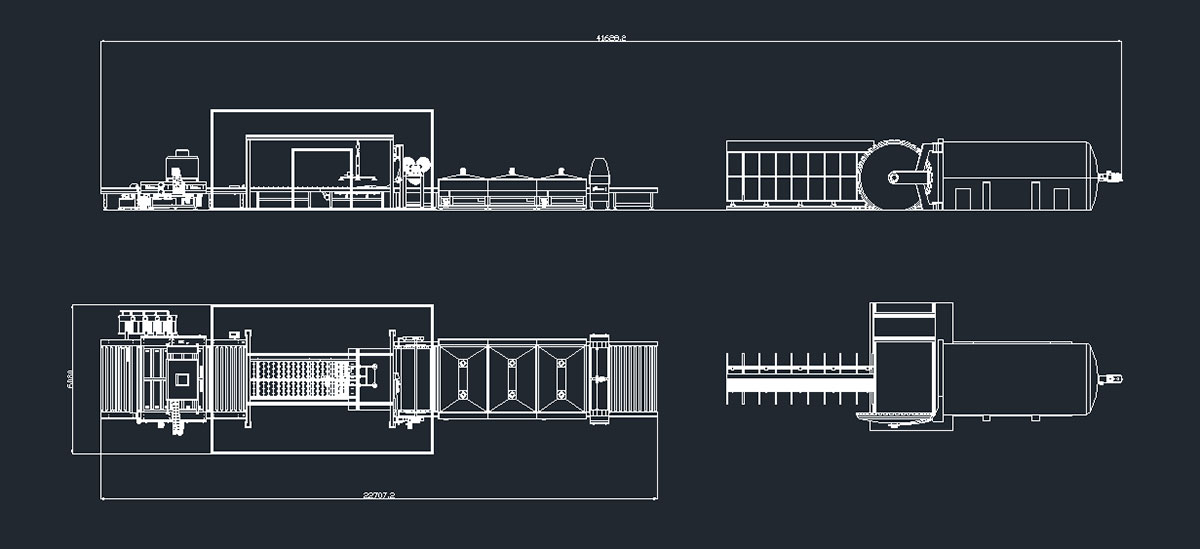

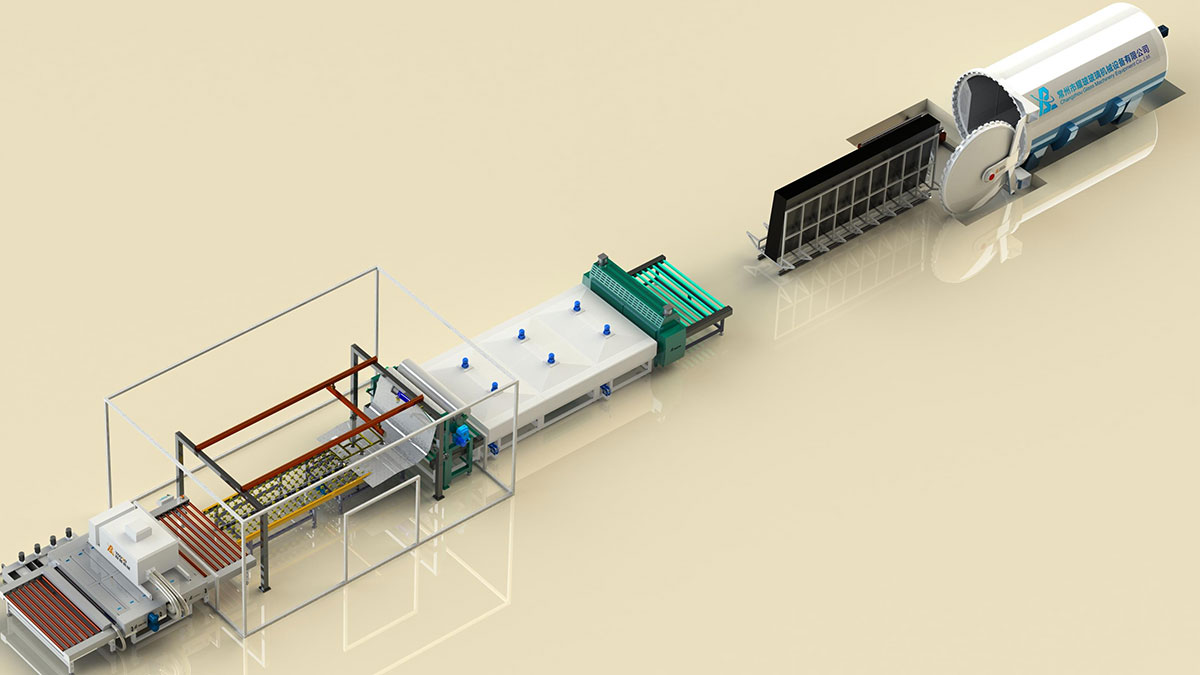

半自动夹层玻璃生产线主要由:玻璃清洗干燥机、合片台、简式行走吸盘、电动PVB胶膜(mó)铺摊机、三段胶(jiāo)膜加热机、终压机以及高(gāo)压釜等设备组(zǔ)成,

其主要适合于小批量生产,规格品种较(jiào)多的定制生产, 夹胶玻璃该设备(bèi)有以下几大特点:

1、全线完(wán)整而有效的集成智能化(huà)控制系统,并采用上位机(jī)监控PLC几种控制,触摸(mō)屏显示及(jí)操作;

2、玻璃清洗干燥机设计合理,上部毛(máo)刷,胶辊及风力根据厚度同时升降,较大行程(chéng)可(kě)达300mm,升降控制可通过PLC自动控制;

3、合片(piàn)室内的行走(zǒu)吸盘吊架可人工操作(zuò),简便的行(háng)走到相对位置,将多片(piàn)玻璃精确叠合误差<±0.5mm;

4、合片台设计可升降作业工作台面,电动PVB胶膜字自动放(fàng)膜和收膜,膜筒数量可1-5卷膜选择(zé)配置(zhì);

5、预压机更具独特设计和极高的配置实现玻璃的出示压合成形,加(jiā)热机通过红外加热管对玻璃进行加热,

每根加热管1.8~2.0kW,每台配(pèi)置(zhì) 24根(gēn)(上12根下12根),可更均匀的(de)加热,具有更高的热(rè)效率,

同时主加热区设(shè)有热循环可实现均匀加热;

6、高压(yā)釜采用PLC程序(xù)自动化控制,安装有外接(jiē)线(xiàn)加热元件及独特的(de)循环系统和水冷却(què)系统,安全(quán)可靠,

安全可靠,操作简单,每釜(fǔ)的工作循环(huán)时间短;

7、生产较为灵活,操作比较简(jiǎn)单,工人相对培训成本较低。

Semi-automatic laminated glass production line is mainly composed of: glass washing and drying machine, lamination table, simple walking sucker, electric PVB film laying machine, three-section film heating machine, final press and autoclave and other equipment.

It is mainly suitable for small batch production, more specifications and varieties of custom production, laminated glass equipment has the following characteristics:

1, complete and effective integrated intelligent control system, and the use of upper computer monitoring PLC control, touch screen display and operation;

2, glass cleaning and drying machine design is reasonable, the upper brush, cots and wind according to the thickness of the lifting at the same time, the maximum travel up to 300mm, lifting control can be automatically controlled by PLC;

3, the walking sucker hanger in the closing chamber can be manually operated, easy to walk to the relative position, and the accurate overlapping error of multiple pieces of glass is < ±0.5mm;

4. The design of the closing table can lift the working table, the electric PVB film word automatically release film and receive film, the number of film canisters can be 1-5 film selection configuration;

5, the prepress has a unique design and extremely high configuration to achieve the composite shape of the glass. The heating machine heats the glass through the infrared heating tube.

Each heating pipe 1.8~2.0kW, each unit is equipped with 24 (12 upper and 12 lower), can be more uniform heating, with higher thermal efficiency,

At the same time, the main heating area is provided with a thermal cycle to realize uniform heating;

6, autoclave adopts PLC program automatic control, installed with external wiring heating element and unique circulation system and water cooling system, safe and reliable,

Safe and reliable, simple operation, short working cycle time of each kettle;

7. The production is flexible, the operation is simple, and the cost of training workers is relatively low.